- Solutions

- Products

- All Products

- Favorites

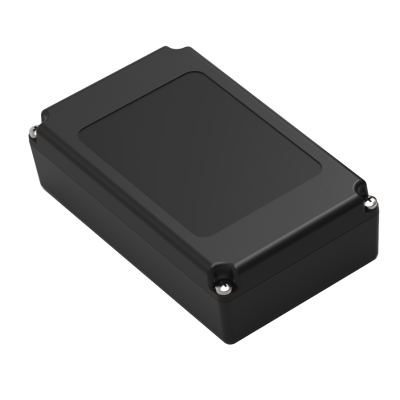

Vega MT-5GNSS Tracker | Internal Antennas | CAN/RS-485 | BLE

Vega MT-5GNSS Tracker | Internal Antennas | CAN/RS-485 | BLE Vega MT X IntGNSS Tracker | Internal Antennas | Built-in Battery | CAN

Vega MT X IntGNSS Tracker | Internal Antennas | Built-in Battery | CAN Vega MT X ExtGNSS Tracker | External Antennas | Built-in Battery | CAN

Vega MT X ExtGNSS Tracker | External Antennas | Built-in Battery | CAN Vega MT X LTEGNSS Tracker | External Antennas | Built-in Battery | CAN | LTE modem

Vega MT X LTEGNSS Tracker | External Antennas | Built-in Battery | CAN | LTE modem Vega MT-21GNSS Tracker | Internal Antennas | Without Battery

Vega MT-21GNSS Tracker | Internal Antennas | Without Battery Vega MT-22GNSS Tracker | Internal Antennas | With Battery | Voice Communication

Vega MT-22GNSS Tracker | Internal Antennas | With Battery | Voice Communication Vega MT-23GNSS Tracker | Internal Antennas | With Battery

Vega MT-23GNSS Tracker | Internal Antennas | With Battery Vega MT-24GNSS Tracker | Internal Antennas | With Battery | CAN-processor

Vega MT-24GNSS Tracker | Internal Antennas | With Battery | CAN-processor Vega MT-25GNSS Tracker | External GNSS antenna | With Battery | CAN-processor | Voice

Vega MT-25GNSS Tracker | External GNSS antenna | With Battery | CAN-processor | Voice Vega M100GNSS Beacon | 3000 mAh | IP54

Vega M100GNSS Beacon | 3000 mAh | IP54 Vega M110GNSS Beacon | 3000 mAh | IP67

Vega M110GNSS Beacon | 3000 mAh | IP67 Vega M200GNSS Beacon | 3000 mAh | IP54 | RF tag

Vega M200GNSS Beacon | 3000 mAh | IP54 | RF tag Vega M210GNSS Beacon | 3000 mAh | IP67 | RF tag

Vega M210GNSS Beacon | 3000 mAh | IP67 | RF tag Vega M300GNSS Beacon | 3000 mAh | IP54 | RF tag | Engine locking relay

Vega M300GNSS Beacon | 3000 mAh | IP54 | RF tag | Engine locking relay Vega M310GNSS Beacon | 3000 mAh | IP67 | RF tag | Engine locking relay

Vega M310GNSS Beacon | 3000 mAh | IP67 | RF tag | Engine locking relay Vega M50GNSS Beacon | 1500 mAh | IP54

Vega M50GNSS Beacon | 1500 mAh | IP54 Vega M410GNSS Beacon | 12800 mAh | IP67 | 2 SIM

Vega M410GNSS Beacon | 12800 mAh | IP67 | 2 SIM Vega MX600LGNSS Beacon | 3000 mAh | IP67 | 2 SIM | BLE 5.0

Vega MX600LGNSS Beacon | 3000 mAh | IP67 | 2 SIM | BLE 5.0 Vega MX500GNSS Beacon | 3000 mAh | IP50 | 2 SIM | BLE 5.0

Vega MX500GNSS Beacon | 3000 mAh | IP50 | 2 SIM | BLE 5.0 Vega MX510GNSS Beacon | 3000 mAh | IP65/IP67 | 2 SIM | BLE 5.0

Vega MX510GNSS Beacon | 3000 mAh | IP65/IP67 | 2 SIM | BLE 5.0 Vega MX710GNSS Beacon | 12800 mAh | IP67 | 2 SIM | BLE 5.0

Vega MX710GNSS Beacon | 12800 mAh | IP67 | 2 SIM | BLE 5.0 Vega MX810GNSS Beacon | 5300 mAh | IP67 | 2 SIM | BLE 5.0

Vega MX810GNSS Beacon | 5300 mAh | IP67 | 2 SIM | BLE 5.0 Vega RK-2.4Radio Channel Pack | Reader | Engine locking relay | RF tag

Vega RK-2.4Radio Channel Pack | Reader | Engine locking relay | RF tag Vega SM-1Microphone

Vega SM-1Microphone ButtonsButtons

ButtonsButtons IndicatorsLight Indicators | Sound Indicators

IndicatorsLight Indicators | Sound Indicators Vega ST-1Temperature Sensor

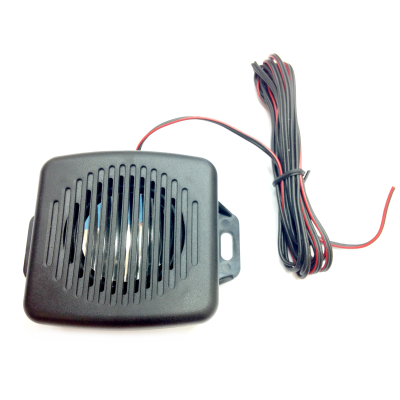

Vega ST-1Temperature Sensor Vega SD-1Speaker

Vega SD-1Speaker GLONASS/GPS AntennasGLONASS/GPS Antennas

GLONASS/GPS AntennasGLONASS/GPS Antennas GSM AntennasGSM Antennas

GSM AntennasGSM Antennas Connectors with WiresConnectors with Wires | Fuse Holder

Connectors with WiresConnectors with Wires | Fuse Holder Vega K-232UART<–>RS-232 converter | Power output 5 V

Vega K-232UART<–>RS-232 converter | Power output 5 V Vega SA-1Antijammer | Open drain output

Vega SA-1Antijammer | Open drain output Vega RP-1Port replicator | 4 open drain outputs | 6 multifunctional inputs

Vega RP-1Port replicator | 4 open drain outputs | 6 multifunctional inputs Vega RP-2Port replicator | 4 open drain outputs | 6 multifunctional inputs

Vega RP-2Port replicator | 4 open drain outputs | 6 multifunctional inputs Destination Display Boardsin assortment | for Bus & Tram

Destination Display Boardsin assortment | for Bus & Tram Vega BLE moduleInternal BLE antenna | BLE 5.0 | IP40

Vega BLE moduleInternal BLE antenna | BLE 5.0 | IP40 Vega MT-5

Vega MT-5 ESCD

ESCD - The list is empty. Add products to your favorites and they will appear here

- GNSS Trackers

- GNSS Beacons

Vega M100GNSS Beacon | 3000 mAh | IP54

Vega M100GNSS Beacon | 3000 mAh | IP54 Vega M110GNSS Beacon | 3000 mAh | IP67

Vega M110GNSS Beacon | 3000 mAh | IP67 Vega M50GNSS Beacon | 1500 mAh | IP54

Vega M50GNSS Beacon | 1500 mAh | IP54 Vega M410GNSS Beacon | 12800 mAh | IP67 | 2 SIM

Vega M410GNSS Beacon | 12800 mAh | IP67 | 2 SIM Vega MX600LGNSS Beacon | 3000 mAh | IP67 | 2 SIM | BLE 5.0

Vega MX600LGNSS Beacon | 3000 mAh | IP67 | 2 SIM | BLE 5.0 Vega MX500GNSS Beacon | 3000 mAh | IP50 | 2 SIM | BLE 5.0

Vega MX500GNSS Beacon | 3000 mAh | IP50 | 2 SIM | BLE 5.0 Vega MX510GNSS Beacon | 3000 mAh | IP65/IP67 | 2 SIM | BLE 5.0

Vega MX510GNSS Beacon | 3000 mAh | IP65/IP67 | 2 SIM | BLE 5.0 Vega MX710GNSS Beacon | 12800 mAh | IP67 | 2 SIM | BLE 5.0

Vega MX710GNSS Beacon | 12800 mAh | IP67 | 2 SIM | BLE 5.0 Vega MX810GNSS Beacon | 5300 mAh | IP67 | 2 SIM | BLE 5.0

Vega MX810GNSS Beacon | 5300 mAh | IP67 | 2 SIM | BLE 5.0

- Additional Equipment

Vega RK-2.4Radio Channel Pack | Reader | Engine locking relay | RF tag

Vega RK-2.4Radio Channel Pack | Reader | Engine locking relay | RF tag Vega SM-1Microphone

Vega SM-1Microphone ButtonsButtons

ButtonsButtons IndicatorsLight Indicators | Sound Indicators

IndicatorsLight Indicators | Sound Indicators Vega ST-1Temperature Sensor

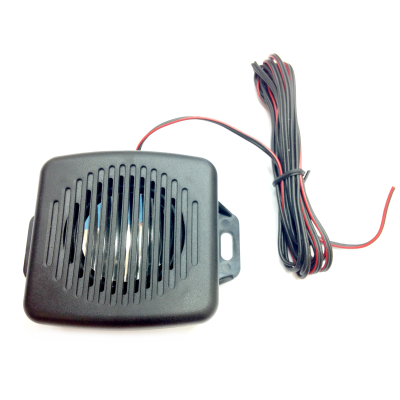

Vega ST-1Temperature Sensor Vega SD-1Speaker

Vega SD-1Speaker GLONASS/GPS AntennasGLONASS/GPS Antennas

GLONASS/GPS AntennasGLONASS/GPS Antennas GSM AntennasGSM Antennas

GSM AntennasGSM Antennas Connectors with WiresConnectors with Wires | Fuse Holder

Connectors with WiresConnectors with Wires | Fuse Holder Vega K-232UART<–>RS-232 converter | Power output 5 V

Vega K-232UART<–>RS-232 converter | Power output 5 V Vega SA-1Antijammer | Open drain output

Vega SA-1Antijammer | Open drain output Vega RP-2Port replicator | 4 open drain outputs | 6 multifunctional inputs

Vega RP-2Port replicator | 4 open drain outputs | 6 multifunctional inputs Vega BLE moduleInternal BLE antenna | BLE 5.0 | IP40

Vega BLE moduleInternal BLE antenna | BLE 5.0 | IP40 ESCD

ESCD

- Devices Archive

Vega MT-21GNSS Tracker | Internal Antennas | Without Battery

Vega MT-21GNSS Tracker | Internal Antennas | Without Battery Vega MT-22GNSS Tracker | Internal Antennas | With Battery | Voice Communication

Vega MT-22GNSS Tracker | Internal Antennas | With Battery | Voice Communication Vega MT-23GNSS Tracker | Internal Antennas | With Battery

Vega MT-23GNSS Tracker | Internal Antennas | With Battery Vega MT-24GNSS Tracker | Internal Antennas | With Battery | CAN-processor

Vega MT-24GNSS Tracker | Internal Antennas | With Battery | CAN-processor Vega MT-25GNSS Tracker | External GNSS antenna | With Battery | CAN-processor | Voice

Vega MT-25GNSS Tracker | External GNSS antenna | With Battery | CAN-processor | Voice Vega M200GNSS Beacon | 3000 mAh | IP54 | RF tag

Vega M200GNSS Beacon | 3000 mAh | IP54 | RF tag Vega M210GNSS Beacon | 3000 mAh | IP67 | RF tag

Vega M210GNSS Beacon | 3000 mAh | IP67 | RF tag Vega M300GNSS Beacon | 3000 mAh | IP54 | RF tag | Engine locking relay

Vega M300GNSS Beacon | 3000 mAh | IP54 | RF tag | Engine locking relay Vega M310GNSS Beacon | 3000 mAh | IP67 | RF tag | Engine locking relay

Vega M310GNSS Beacon | 3000 mAh | IP67 | RF tag | Engine locking relay Vega RP-1Port replicator | 4 open drain outputs | 6 multifunctional inputs

Vega RP-1Port replicator | 4 open drain outputs | 6 multifunctional inputs

- Software

- Dealers map

- Info

- Company

- Updates

- Service maintenance

- Technical support

The office occupies two adjacent buildings and includes production facilities, office premises and warehouses. Here, almost the entire production cycle takes place from the idea to the shipment of th

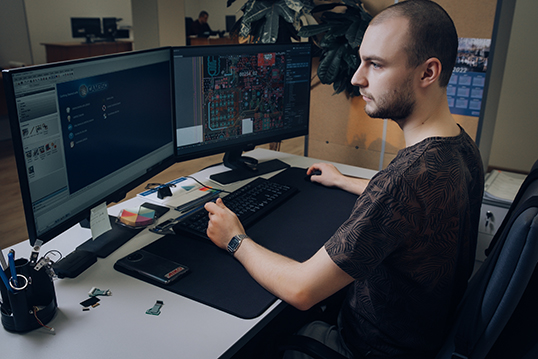

The office occupies two adjacent buildings and includes production facilities, office premises and warehouses. Here, almost the entire production cycle takes place from the idea to the shipment of th Our engineers are engaged in the development of circuits for printed circuit boards at a high level.

Our engineers are engaged in the development of circuits for printed circuit boards at a high level. The PCB layout is carried out by highly qualified specialists.

The PCB layout is carried out by highly qualified specialists. Suitable for specific device and comfortable in using housing design is developed at first.

Suitable for specific device and comfortable in using housing design is developed at first. Our specialists design molds for molding casings on modern equipment in our production in the Berdsk city.

Our specialists design molds for molding casings on modern equipment in our production in the Berdsk city. The CNC milling machine makes it possible to manufacture molds of complex shapes.

The CNC milling machine makes it possible to manufacture molds of complex shapes. Specialists manually finish the mold making if it's necessary.

Specialists manually finish the mold making if it's necessary. Casing casting is carried out on modern equipment.

Casing casting is carried out on modern equipment. Leading engineers of the IT department carry out the development, testing and support of software products.

Leading engineers of the IT department carry out the development, testing and support of software products. Our company pays much attention to the software part of the product, because this is the guarantee of its smooth operation.

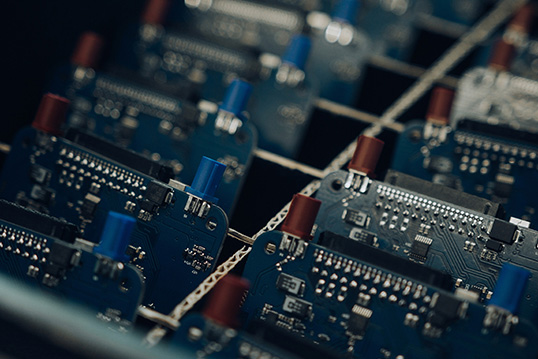

Our company pays much attention to the software part of the product, because this is the guarantee of its smooth operation. Surface mounting of SMD-components is carried out on two modern automatic lines operating simultaneously.

Surface mounting of SMD-components is carried out on two modern automatic lines operating simultaneously. Qualified employees supervise the production process, provide training and maintenance of the line.

Qualified employees supervise the production process, provide training and maintenance of the line. The YAMAHA YSM20 SMD component installation machine can install up to 90,000 components per hour.

The YAMAHA YSM20 SMD component installation machine can install up to 90,000 components per hour. The electric cutter will quickly and qualitatively separate the group blanks of the printed circuit boards for further work.

The electric cutter will quickly and qualitatively separate the group blanks of the printed circuit boards for further work. Our company produces wires for all its needs independently.

Our company produces wires for all its needs independently. The automatic line Gamma 255 allows you to cut the wires and perform their crimping by contacts according to the program programmed by the operator.

The automatic line Gamma 255 allows you to cut the wires and perform their crimping by contacts according to the program programmed by the operator. The automatic line KODERA allows to cut the wires with length up to 4 meters.

The automatic line KODERA allows to cut the wires with length up to 4 meters. The automatic line controls the quality of the produced contacts. After that an each connector is assembled and checked manually.

The automatic line controls the quality of the produced contacts. After that an each connector is assembled and checked manually. More than ten qualified installers of radio electronic equipment work in our company.

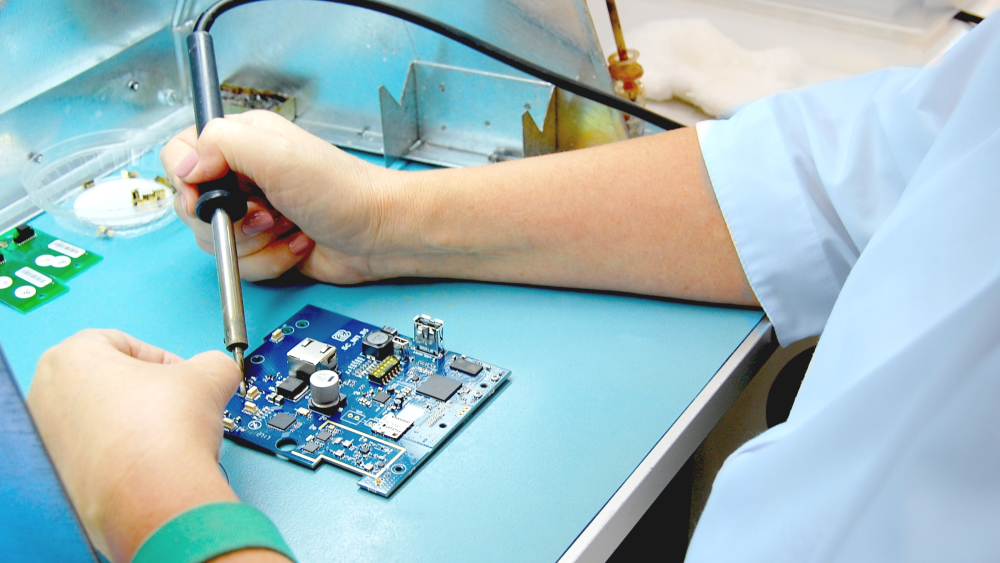

More than ten qualified installers of radio electronic equipment work in our company. Workplaces are equipped with everything necessary.

Workplaces are equipped with everything necessary. All products are subject to mandatory and thorough testing by experienced employees.

All products are subject to mandatory and thorough testing by experienced employees. The devices are packed in individual containers according to the delivery kit.

The devices are packed in individual containers according to the delivery kit. At the packaging site, the staff quickly and accurately completes the order.

At the packaging site, the staff quickly and accurately completes the order. Individual approach to each client is guaranteed.

Individual approach to each client is guaranteed.